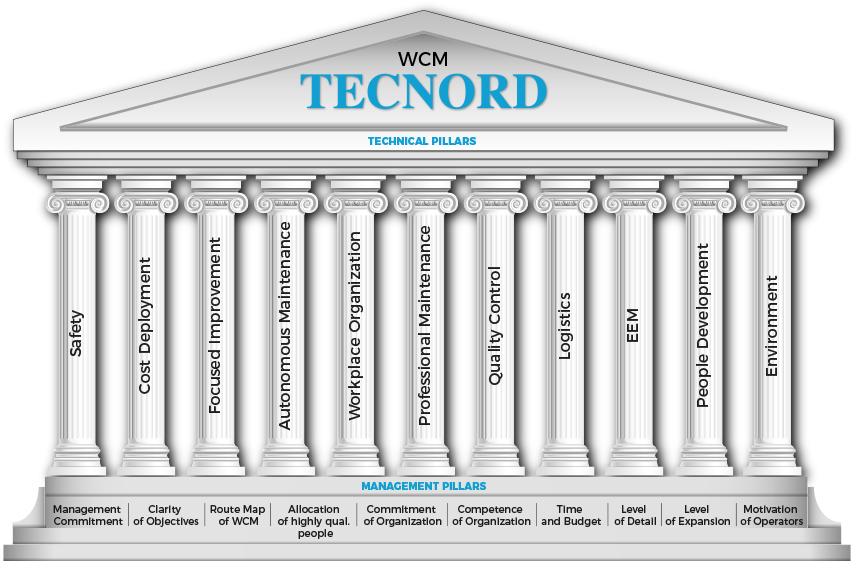

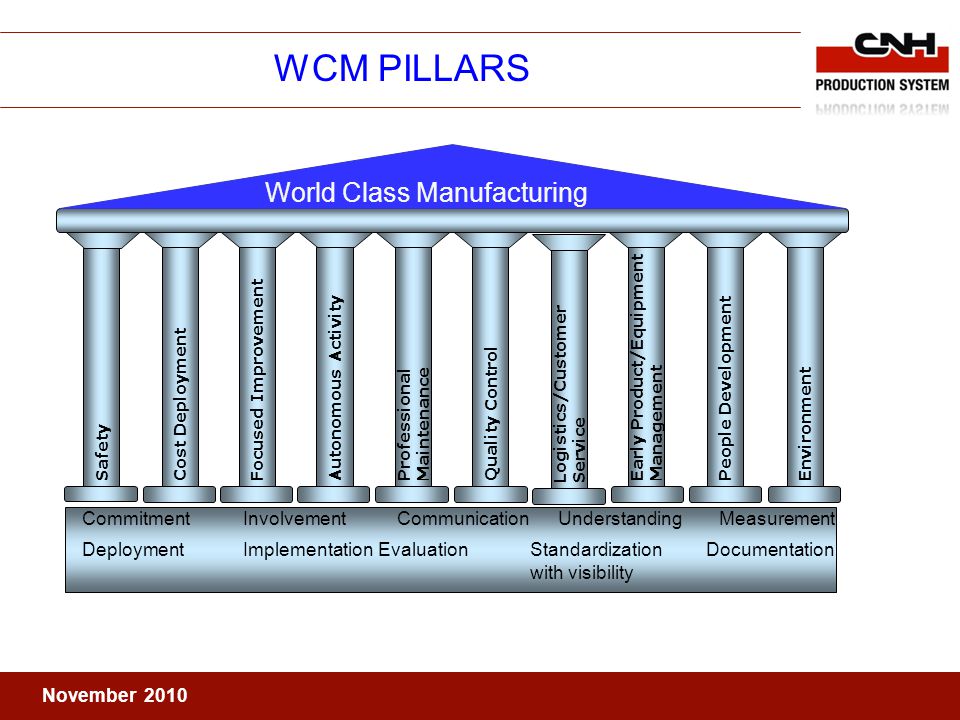

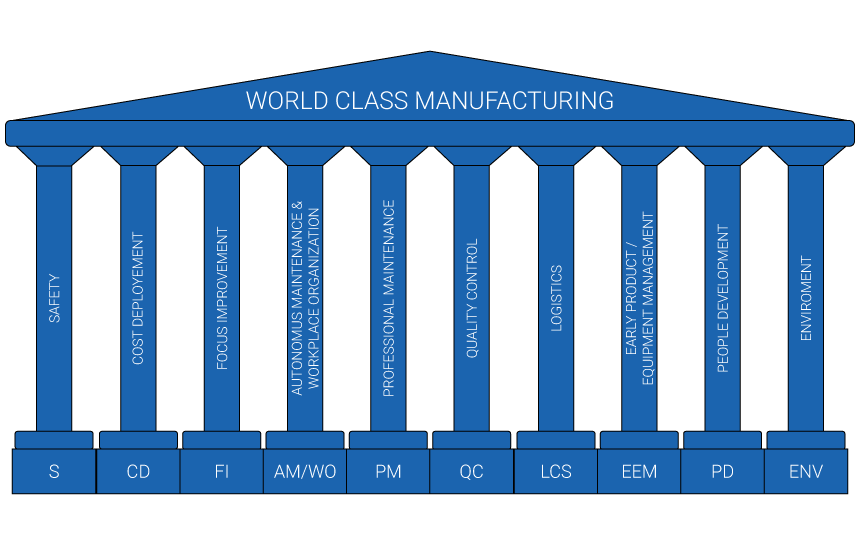

world class manufacturing pillars

Admittedly there are fewer giant bottles of champagne when Manufacturing. In 2014 14277 projects were implemented within WCM generating savings of 1956 million.

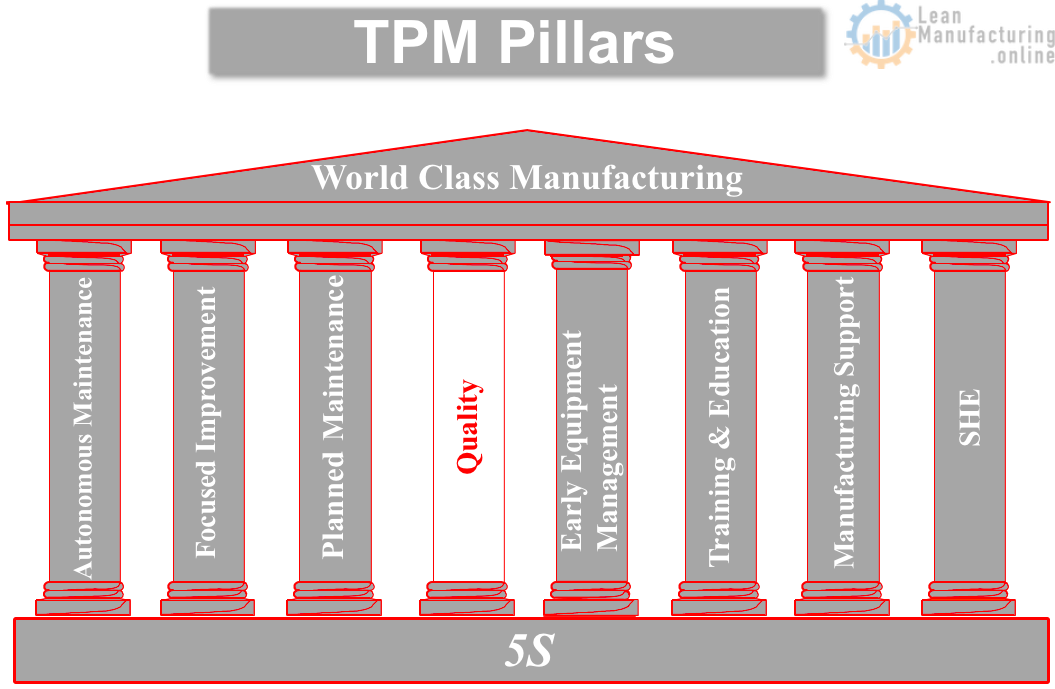

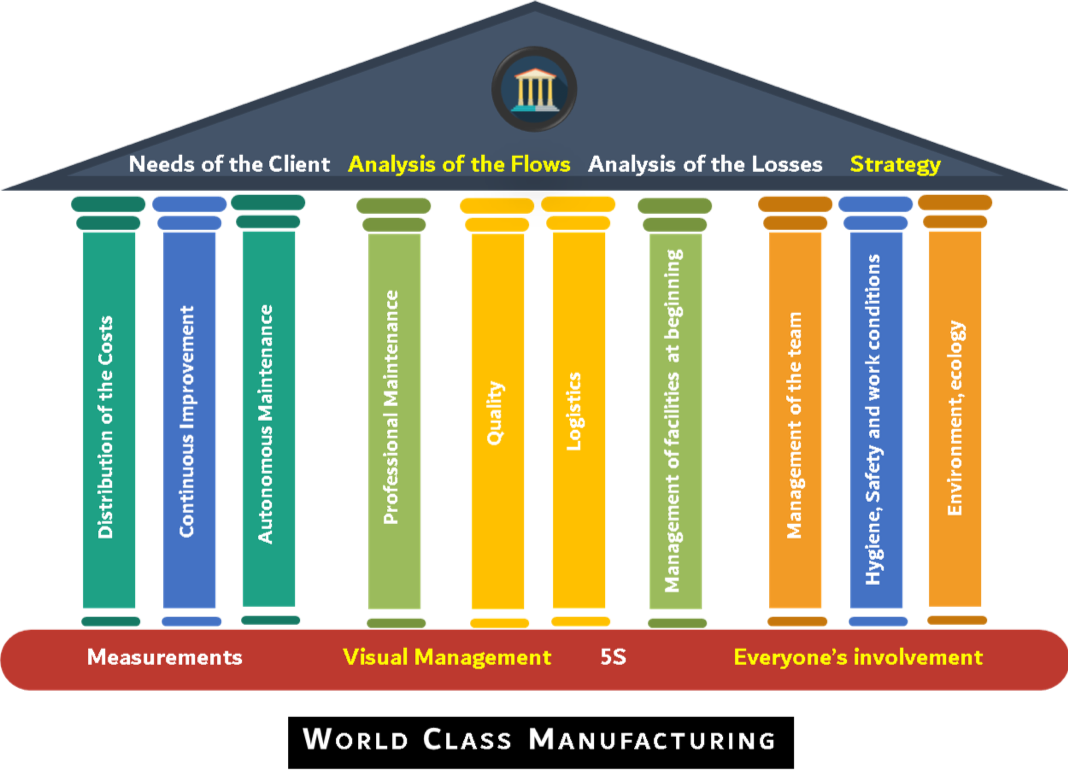

Eight Pillars Of Total Productive Maintenance 5s Foundation World Class Manufacturing Roof Quality Continuously Improving Manufacturing

What is World Class Manufacturing.

. World Class Reliability performance can be considered a worn- out cliché by many because it is so difficult to achieve and never seems to be possible for most manufacturing facilities. There are three main principles which drive world-class manufacturing. Implementation of just in time and lean management leads to reduction in wastage thereby reduction in cost.

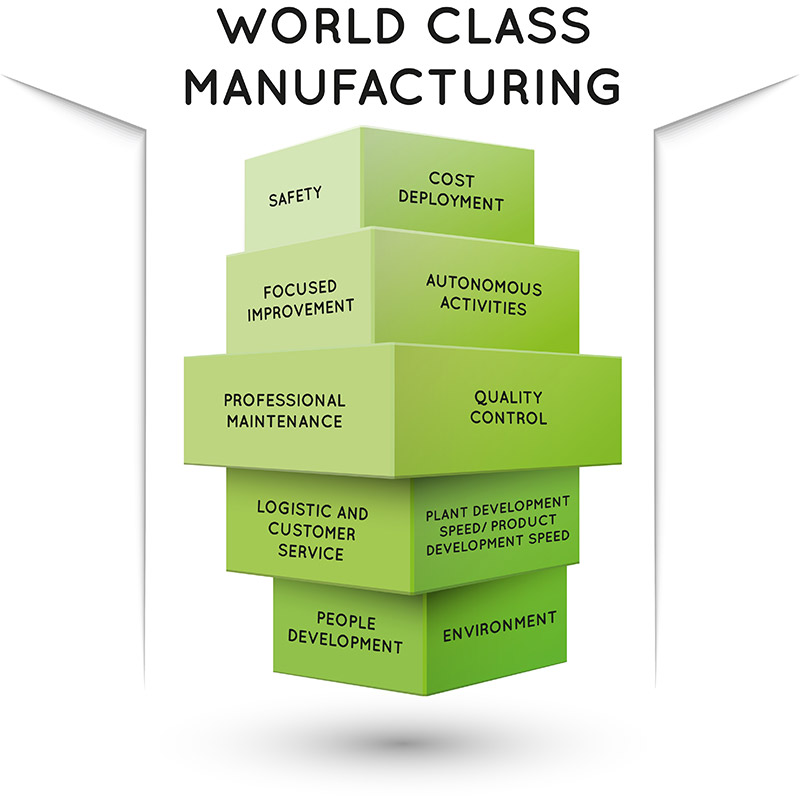

Based on some pillars that will be presented later this methodology focuses on best practices for management with zero-waste. Download scientific diagram World Class Manufacturing pillars from publication. A more flexible approach to meeting customer needs.

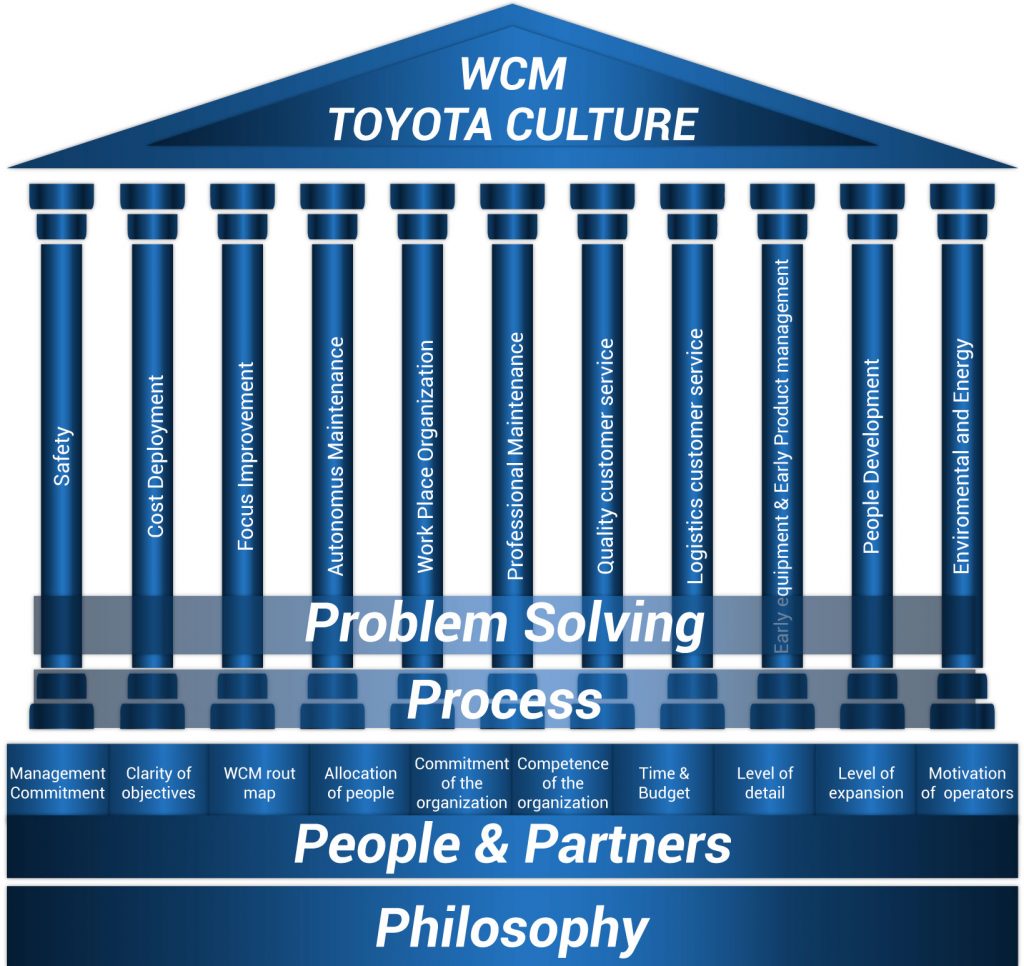

Purpose The paper aims to investigate the best common management practices of the worldclass companies identified in Brazil and Japan. In the mid-1980s when Toyota. Change in management of the workforce.

In the mid-1980s when Toyota increasingly. World Class Safety provides a model to establish understand measure and improve safety standards. Resolve problems that cause poor.

Pillars Support on Three Levels Seek the Loss Investigates the losses that are having an effect on the KPIs. The balanced scorecard and seven. Implementation of total quality management leads to reduction of defects and encourages zero tolerance towards defects.

Culture Prevention Compliance Capability CARES C oaching A ssociates to R einforce Excellence and S afety. World Class Manufacturing WCM is a comprehensive management system designed to improve business performance through loss elimination. Research excellence for us means to invest in the future of health for the world.

Resources are focused on reducing breakdowns improving quality improving customer satisfaction and improving productivity. Both require an unwavering commitment to excellence and continuous improvement from every member of the organisation. Managerial pillars overview Safety steps 1-3 pillar basics overview Loss Waste concept.

Posted in unikunjbhoraniya 1 point and 0 comments. WORLD CLASS MANUFACTURING 5 6 W o r l d C l a s s M a n u f a c t u r i n g Supporting Pillars of World Class Manufacturing A new approach to quality. WCM is a mindset based on a continuous improvement approach 2.

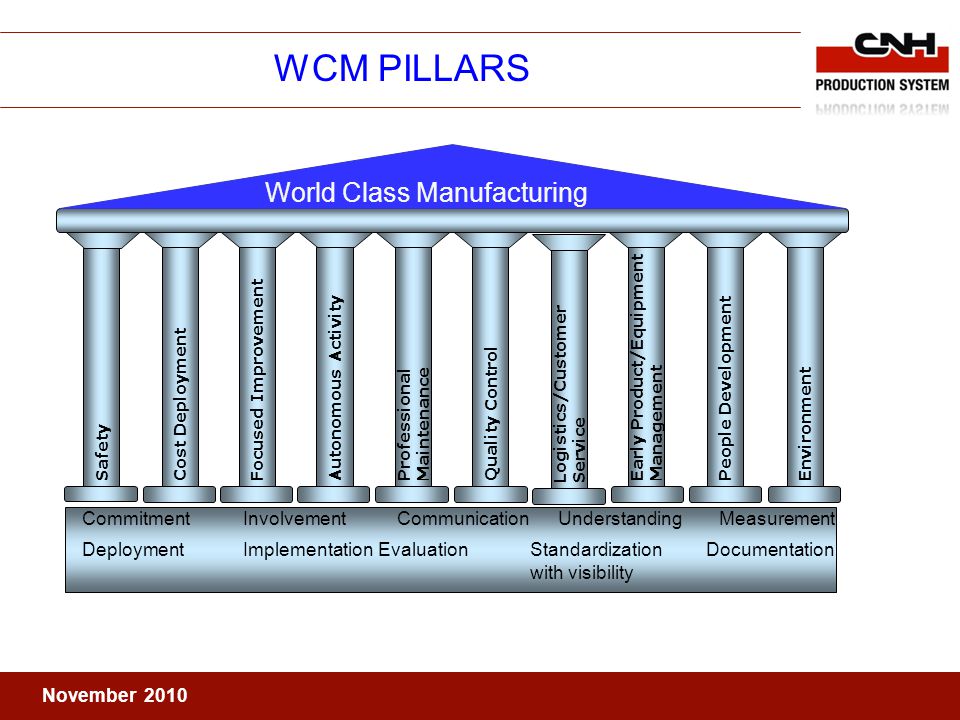

Develops a master plan. Safety Program Icons and Mottos Everyone goes home safe every day everywhere. At CNH Industrial the use of tools for sharing information and collecting suggestions is well established.

If this sounds familiar its because WCM shares countless similarities with Lean philosophy. The pillars of World Class Manufacturing are specified in terms of Technical and. Knowledge Management and World Class Manufacturing.

The ten pillars of World Class Manufacturing. As we explored last time the process of becoming a World Class Manufacturing WCM organisation is similar to becoming a World Class F1 winning team. WCM professionals thus have the responsibility of coordinating the design execution.

Our expertise rest on the pillars of our advanced RD capabilities world-class manufacturing facilities our long legacy of trust and our partnerships. Just In Time manufacturing techniques. If this sounds familiar its because WCM shares countless similarities with Lean philosophy.

An initial approach based on a. Based on some pillars that will be presented later this methodology focuses on best practices for management with zero waste. As a result of good systems procedures and employee focus World Class Reliability facilities will always have excellent safety programs.

WCM World Class Manufacturing is a set of management principles and techniques. In 2014 about 395 thousand suggestions were collected across the plants where WCM principles are applied with an average of 11 per employee. Develop and Deliver World Class Training Consulting Industry 40 Digitalization.

And propose a business model aimed at helping companies to achieve worldclass level of excellence. Manufacturing quality engineering logistics design and HR managers Prerequisites. Designmethodologyapproach A crosssectional survey is the methodology employed.

WCM World Class Manufacturing is a set of management principles and techniques. Principles of World Class Manufacturing. The implementation and management of WCM involves continuously capturing and analysing data tracking reporting and counteracting losses and directing initiatives for continuous improvement of production processes.

Wcm Pillars Description And Features Business Building Information

Work Place Integration Fca Group

Cosa Vuol Dire Supportare Metodologie Wcm World Class Manufacturing Next

World Class Manufacturing Pillars Download Scientific Diagram

World Class Manufacturing Or Wcm What Is It

Quality Maintenance An Essential Pillar For World Class Manufacturing

The World Class Manufacturing Framework 13 Download Scientific Diagram

World Class Manufacturing Ind Alfra Lean Advisors

Wcm World Class Manufacturing Organization Of Production Itcl

Pillars Description And Features Open Textbooks For Hong Kong

November 2010 Wcm Pillars World Class Manufacturing Cost Deployment Autonomous Activity Professionalmaintenancequality Controllogistics Customerserviceearly Ppt Download

What Is World Class Manufacturing In Hindi

World Class Manufacturing Or Wcm What Is It

Illustrates The Ten Pillars Of Wcm Download Scientific Diagram